Slice, then Enhance

Slice, then Enhance with Helio Additive

Assess 3D print success before you commit—then enhance speed & quality, inside your slicer.

We work with the best

Two week free trial

Try Helio in minutes — start free, upgrade when you’re ready

Assess is free. Enhance starts at $9.99/month for personal (non‑commercial) use, or $29.99/month for commercial desktop optimization.

Get started

Activate Helio in Bambu Studio

Run Assess (free) to check risk

Run Enhance when ready, then print

Assess

Free

Run Printability Reports anytime

Enhance

From $9.99/mo

Personal $9.99 • Commercial $29.99 (no cap)

Compatibility

11+ printers

36+ materials

Where it runs

Inside Bambu Studio

Desktop-first workflow

Trial includes unlimited access during the trial. Cancel anytime.

Assess

FREESee issues before printing

Simulates your print to reveal defects early.

- Engineering-grade 3D print diagnosis made simple with 1 click

- Totally free to run, in seconds, in your slicer

- Compatible with 36+ materials and 11+ printers in the Bambu Lab ecosystem

Enhance

From $9.99/moSmarter settings, better prints

Automatically optimizes speed, strength, and reliability.

- 10–40% 3D print speed improvement in minutes

- Automatically optimizes speed, strength, and reliability

- Personal $9.99/mo (non-commercial) • Commercial $29.99/mo (no cap)

Ecosystem

Runs inside Bambu Studio

Built for desktop printing workflows

Helio supports a growing set of desktop printers and materials—so teams can standardize on

one workflow and get reliable results faster.

11+

Desktop printers

36+

Desktop materials

Desktop-first: Bambu Studio integration and a growing compatibility list.

Desktop-first: Bambu Studio integration and a growing compatibility list. Fewer failed prints

Spot risk before you commit time and material.

Less waste

Reduce scrap and reruns with clearer decisions.

Faster print times

Optimize layer-time behavior without guesswork.

More consistent strength/quality

Keep thermal conditions in a workable range.

Value Calculator

For teams & businesses

Quantify what Enhance is worth for your workflow

If you’re producing parts (not just tinkering), speed alone isn’t the goal. You want faster prints without trading away strength or reliability. Enhance automatically optimizes speed, strength, and print consistency—so you can ship parts with fewer reruns.

- See time savings across a typical week/month

- Estimate labor + machine utilization impact

- Account for reduced failures and reruns

- Make the case for upgrades with real numbers

Why it matters

Small per‑part savings compound quickly when you’re running batches. The Value

Calculator helps you decide when Enhance pays for itself.

Best for print farms, service bureaus, and engineering teams shipping functional parts.

Results snapshot

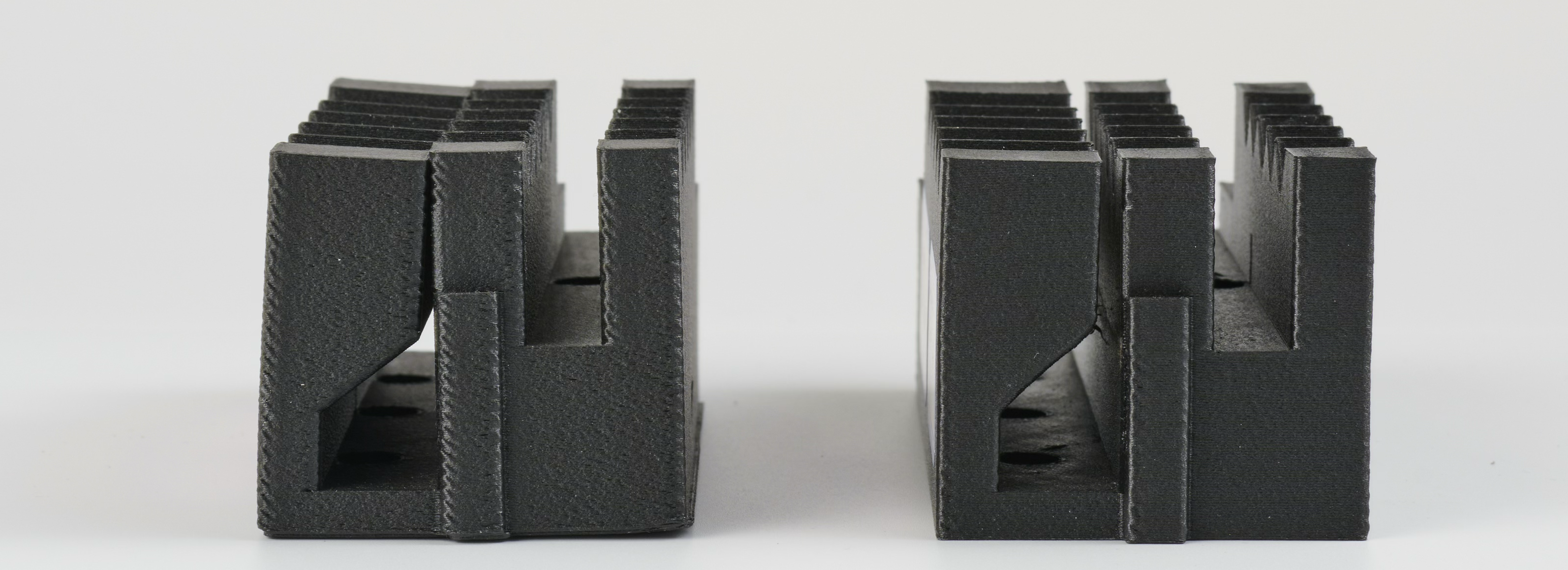

Helio Additive's technology has helped us enhance the Polymaker engineering materials, with faster print times, better strength and less warping.

What changed

- Up to 42% faster 3D prints

- Up to 57% higher thermal quality

- Up to 29% tighter thermal consistency

How it works

A simple flow that fits your existing workflow.

1

Slice

Generate G-code in your slicer as usual.

2

Assess

Simulate and spot risk areas before you 3D print.

3

Enhance

Tune speed/quality while protecting reliability.

4

3D Print

Run the job with fewer surprises and reruns.

Use cases

Common scenarios where Helio adds immediate value.

Resources

Updates, guides, and releases—kept lightweight.

Update

2025-12-15

Helio moves from Alpha to Beta: faster runs, clearer products, simpler pricing

Helio is officially graduating from Alpha to Beta—shipping up to 5× faster runs, clearer product names, a new Printability Report, expanded materials, and simpler personal pricing.